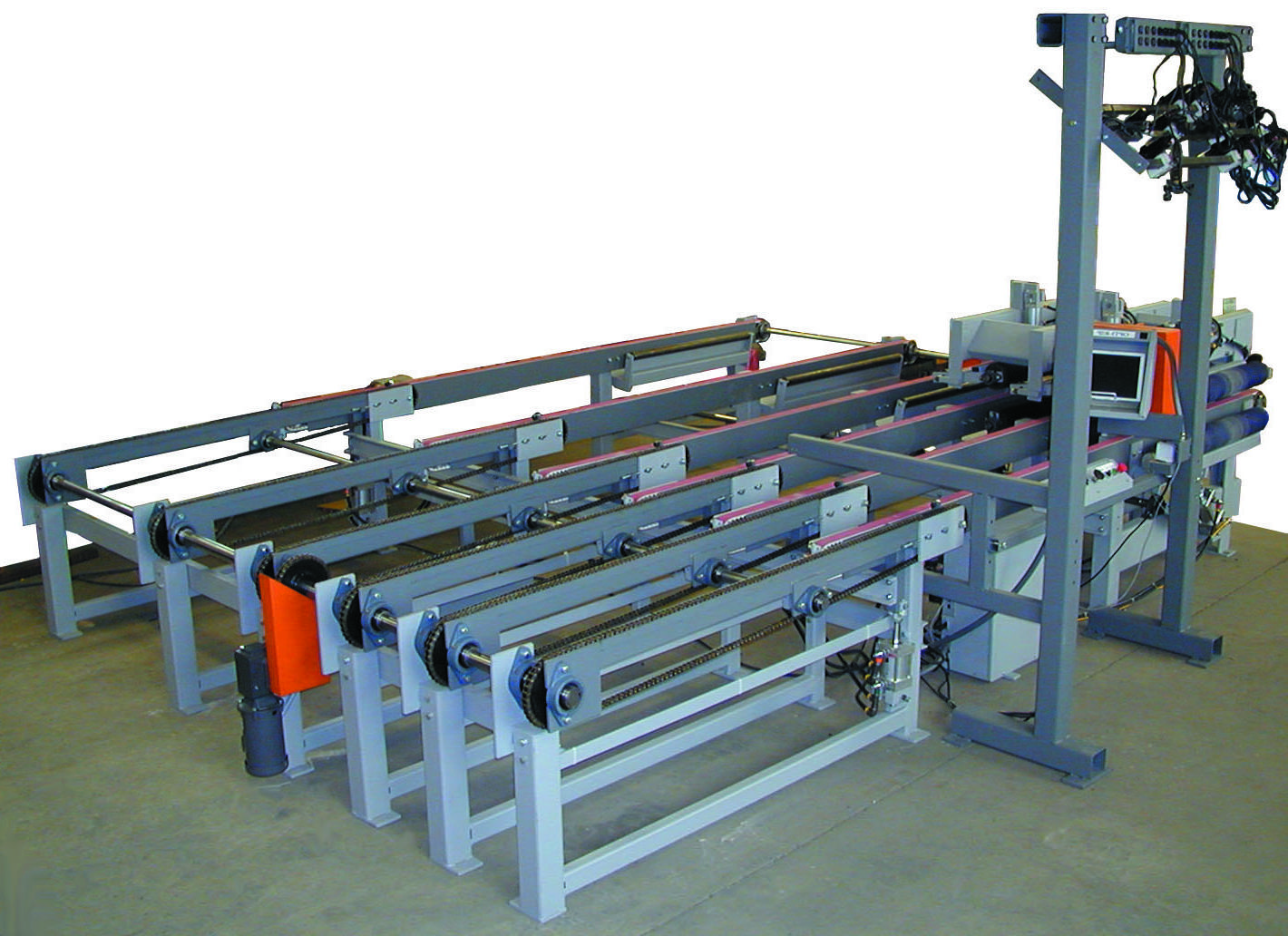

As Movable Blade Rip Saws have become the industry standard, Cameron Automation has continued to push the envelope with (3) Rip Saw Models that it partners with its Industry leading Cameron Infeeds:

卡梅隆锯模型:

- #413A – 12″ Wide (2) Moving Blade, Multiple Fixed Blade Saw

- #413B – 18″ Wide (3) Moving Blade, Multiple Fixed Blade HD Rip Saw

- #413C – 24″ Wide (4) Moving Blade, Multiple Fixed Blade HD Rip Saw

用移动刀片撕裂锯, the potential cut patterns are exponentially increased from a fixed arbor or single blade saw. From the skinniest of boards where you can only cut 1 door stile or rail, to the widest boards where you can cut multiple parts, 模式的数量是无穷无尽的. Because of the number of solutions the moving blades can create, there is no down time to set up the arbor. This makes the whole process of changing from job to job seamless and efficient. The servo driven blades are extremely accurate and fast, and coupled with the Cameron software, 快速改变尺寸.